Proud to be New Zealand Made

This is the story of a three generation family business that flourished from a passion for growing and sheer hard work. The founders were Maria and Walter Van Lier, fondly known to all as Oma and Opa, Dutch for Grandma and Grandpa.

We are incredibly proud to celebrate 74 years of growing and 50 years as an incorporated company.

May 2016 - Steffan Van Lier (3rd generation), Walter Van Lier (founder), Harry Van Lier (3rd generation and owner) and Theo Van Lier (2nd generation and owner).

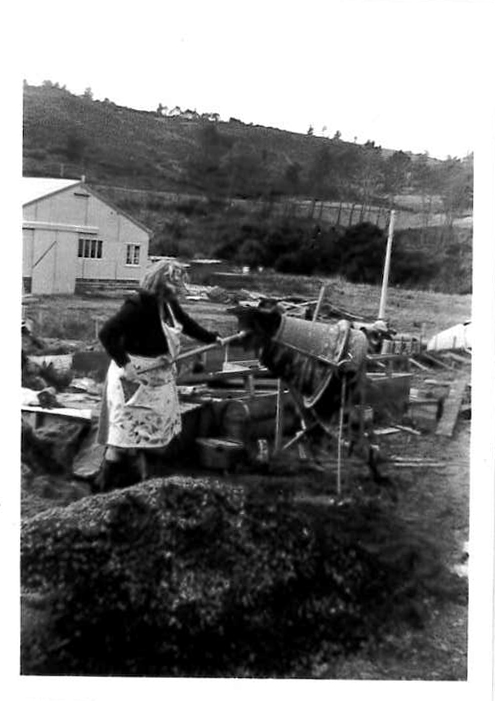

Two acres were purchased on West Coast Road, Oratia, Auckland. In the Dutch work ethic it was all hands to the deck – Maria Van Lier, company founder, is on the end of the shovel helping with the concrete for the foundations of the kit set home they shipped from Holland. The first crop planted here was potatoes. They sold for a pound per sack. An excellent return was made and Walter Van Lier, company founder, said it set them up for flower growing.

In 1967, the nursery was well established with seven glasshouses and several plastic houses. On December 8th 1968, Van Lier Nurseries was incorporated as a limited liability company.

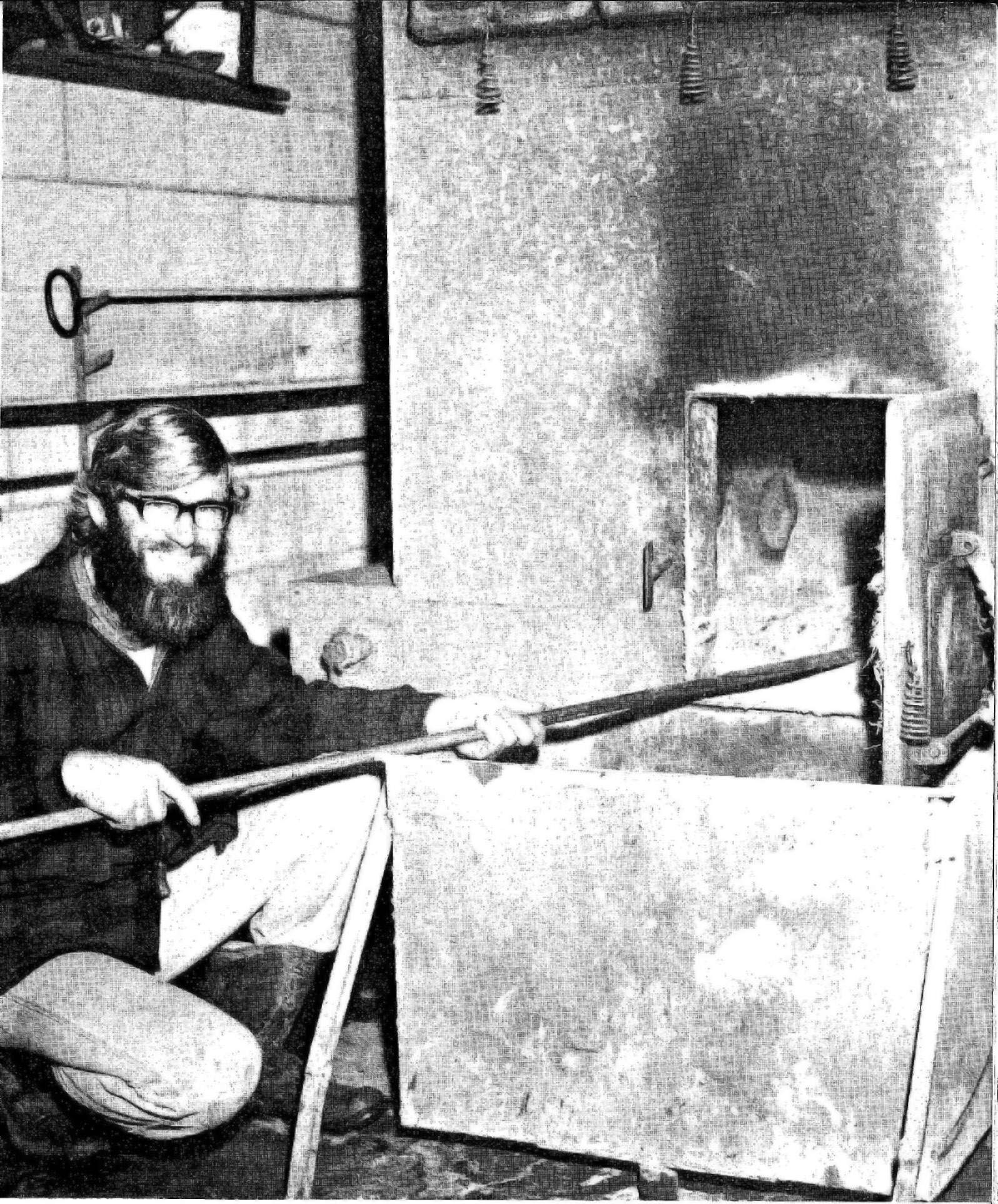

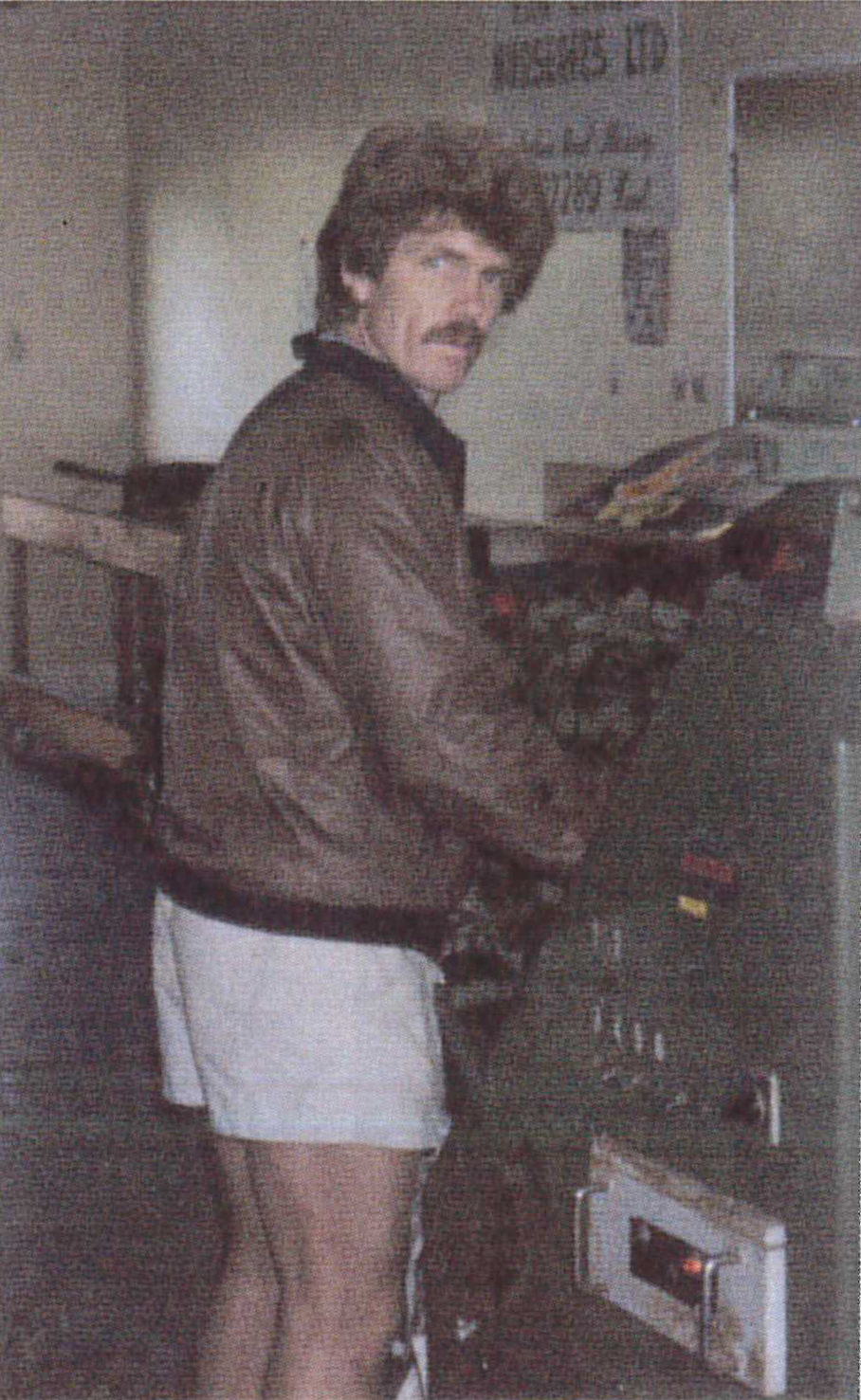

Initially the boiler at Massey was fuelled with oil. As oil prices rose the decision was made to go to a coal fuelled boiler in 1975. Coal is labour intensive and very dirty…Fred is posing for the picture, if he was really cleaning out the firebox he would be covered in black dust!!

A screw unit fed the coal to the boiler but it still required some shovelling which Fred demonstrates.

Walter Van Lier and Mrs. Shalamar bunch carnations by hand in the shed at Massey. Today all of our product is bunched on a processing machine other than Gypsohilia which has to be bunched by hand as it tangles.

Maria van Lier sorts roses by hand while Irene uses an Olimex wrapping machine to wrap the bunch in plastic. This was considered state of the art equipment!

Walter and Fred are surrounded by hundreds of potted cyclamen in a photo that featured on the cover of NZ Coal. At this point 13 glasshouses totalling 10,000 sq metres were heated. Of the 13 heated glasshouses, three were used for pot plants, three for carnations, and the remaining seven houses contained approximately 22,000 rose bushes producing 350,000 rose stems a year.

Maria and Walter are photographed in the pool house at Massey. The occasion was their son Joe’s wedding. The pool house has been the venue for a number of family weddings most recently being Theo’s daughter Suzanna’s wedding in 2014.

A second coal-fired boiler was installed at Massey which has an automatic feed with sloping sides into the auger. It proved to be more efficient and the nursery continued to utilise it until 2017 when ETS tax and the state of repair made it uneconomical.

The Massey Nursery now sported 14 glasshouses, a shadehouse and a very flash coal shed and boiler.

Theo and Wally cultivating soil at Massey. Today we plant our rose, carnation, gypsophilia, parzival, solidago and veronica in cocous bags for better productivity and disease control.

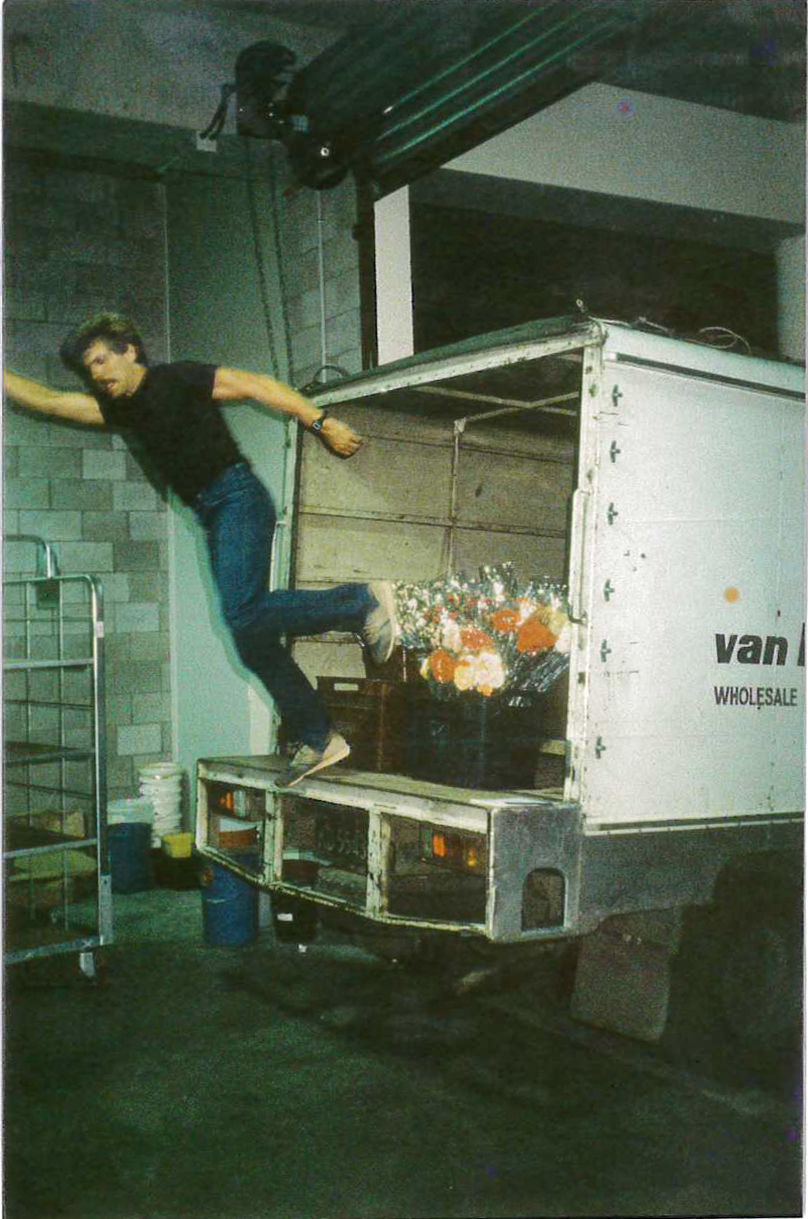

Van Lier delivered their product to the auction themselves up until the late 1990s. Wally is well ahead of his time managing a “motion” photo or "jump shot" without the aid of digital photography!

Van Lier was producing in excess of a million rooted carnation cuttings a year in the late 1980s and early 1990s when carnations were a popular flower.

Van Lier enjoyed a lucrative export market until the late 1980s, air freighting roses and carnations to Canada and East Asia.

Van Lier Roses exhibited themselves regularly at the Ellerslie Flower Show. During these years, they also exhibited at the Mystery Creek Field Days where plants were the focus. In recent years their contribution has been via sponsorship to FLONZI and competitors at the NZ Flower and Garden Show.

Fred Van Berlo and Wally pick roses. My, those fashionable Stubbie shorts were very short!In fact, has Fred even got shorts on?

Theo Van Lier fills the diesel tank. Not sure that this would meet OSH standards these days!

Walter continued to drive the flowers to market in retirement particularly when he had to attend a shareholder meeting.

Suits and masks have always been a very necessary requirement for spraying.

Wally tries the new Jamafa sorting machine. This machine was able to sort into stem length. Cutting and banding was still by hand.

Glasshouse 9, 10,11,12,13 and 14 at Massey looking modern and ship-shape.

A large plastic house was built in the late 1980s to grow varieties such as Alstroemeria that do not require controlled heating. This area is known to all Van Lier staff as George's Area. George has been with the company for 22 years. A dedicated administration building was added in the 1990s.

Walter in retirement tending to the young Phaeleonopsis orchid plants at the Massey nursery. These were not a commercial line for Van Lier Nurseries but Walter grew rather large numbers of them very well!

All the members of the Van Lier clan have worked in the nursery at some point in their lives!

In 1995, a 3,200 sqm Venlo style glasshouse was built on the Western side of the Massey property. The land was at building capacity.

Theo and youngest son Steffan bunching roses by hand at Massey – all available hands are pressed into labour at Valentine’s Day!

In August, the site at 241 Riverhead Road was purchased for a purpose built cut rose production nursery!

The first of three glasshouses at the Riverhead nursery. Also featured are the heat storage tank, day tank, sand filter and dam.

Can you spot Riverhead’s current lunchroom? It is the only remaining building that was part of the original purchase.

An Aweta rose processing machine was sourced from Holland by Hortraco, Australia. The introduction of this new piece of equipment was met with some reservation by the staff. However they quickly mastered the use of it and appreciate the reduction of overtime they now have to work in peak production time.

The machine via sensor can send the rose to the bay that is correct for its stem length. Here it is bunched into 10 stems, banded and cut to uniform stem length.

Van Lier successfully gained an exclusive agency for the David Austin Roses in 2009. It took three years to establish a commercially viable crop of three varieties of David Austin Roses – Juliet, Kiera and Patience. In 2012 Van Lier hosted the launch of the David Austin Roses at The Pavillion, Kohimarama.

The flower industry gathered for the launch and an enjoyable time was had by all.

This is not Joanne’s wedding photo! She was persuaded to donne a bridal gown and model a beautiful David Austin Rose bouquet along with other members of the team.

Prior to building the second 5000 sqm glasshouse at Riverhead the dam had to have the line removed and the camber on the walls corrected. There is no other way to express this – a complete and utter nightmare!

Harry at 6 foot 3 is somewhat lost in the dam. This was probably the only fine day in the process!

The construction of a second 5,000 sqm glasshouse began at the Riverhead nursery. Mud, mud, everywhere!

Two months later – closed in, laser levelled, wed matted and ready for growing gutter installation. Glad to see the end of the mud, well at least until 2017.

This glasshouse’s roof was fitted with diffused glass which allows for more dense planting and higher production per sqm. The rose plants pictured are growing in coco fibre bags.

A successful Pink Breakfast fundraiser - A proud moment for Walter Van Lier and the team.

Extra production from the new 5000sqm glasshouse required extra cool store space. At this time a decision was made to house the bunching machine in a chiller kept at a temperature of 15 degrees. Better for the product and personnel!

Freshly picked roses on their way to the processing chiller (15°) where as part of the cool train process they will stay for a few hours before making their way to the unfinished product chiller (4°) awaiting bunching. This helps the rose acclimate from the high temperatures of the glasshouse to the low temperatures of the storage chiller.

Transporting freshly picked Alstroemeria from the Venlo to the processing shed in Massey while Ebony watches on.

Harry Van Lier completed an internship in a range of nurseries in Holland and Germany in 2014 and spotted Parzival at Tesselar, Holland. It is called a “bust and cut” crop – one flower cut per plant and the plant is pulled out.

Helleborus (Magnificent Bells) were added to the Van Lier range in 2016.

Opa visited Riverhead regularly surveying the crop from his scooter and provided valuable advice on the rose crop. On this visit Millie, Riverhead’s mascot, scored a free ride in his basket. Sadly we lost Opa on October 22nd 2016. His legacy lives on and he would be truly proud of the business as it is today.

Propagation glasshouse and quarantine facility was built at Riverhead. The 1600 sqm glasshouse and the 400 sqm shed are dedicated to the propagation of plants for ourselves, other cut flower growers and watch this space for the new range of indoor pot plants – exciting!

With four controllable climate chambers utilising misting and dual screens for energy and shade now available for propagation, Theo Van Lier is in his element!

This is the hardening off area of the propagation house featuring the pot plant varieties we have been trialing!

We now have three varieties of Gypsophila growing at Massey: XLence, Million Stars and New Love. LED lighting over the gyp crop was introduced with the intention of extending its growing season.

George, Sunny, Phoebe, Rinze and Steffan

This photo was taken as part of a photoshoot for FMG's 2018 Calendar. Pictured are Natalie, Cathy, Bada, Kelli (and Millie the dog), Akiko, Joy, Narisa, Matt, Harry, Joanne, Theo, Jacob, Jay, Wen, John, Sarah, Camille, Kester and Amanda.